To freeze-proof a hand pump, it is common to drill a 1/8” hole in the drop pipe below the frost line so water is drained from the pump and drop pipe. As usual, we went farther and installed a 1/4” gate valve below the frost line. Now, with a simple twist of the handle at the wellhead, water drains from the drop pipe.

Anchoring the Well Head

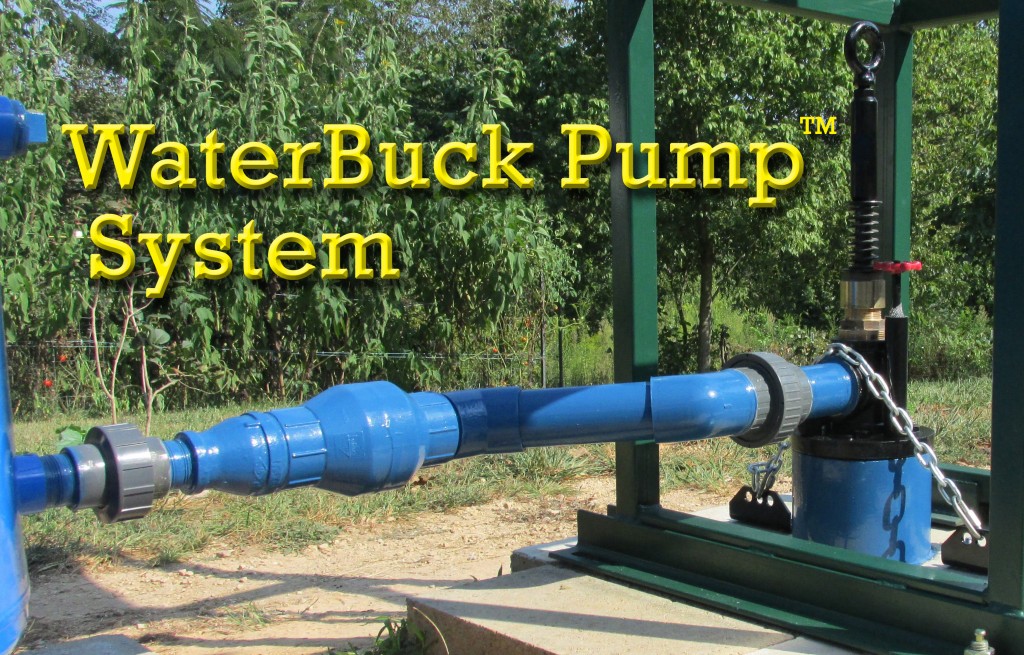

I would never have thought the friction created against the inside of the cylinder wall (when pumping from a deep well with a large cylinder) was so intense that a 500-pound pump system would slip up through a tightened well seal under operation. But it is true! As you can see from the pictures, I had to anchor down the wellhead with chain to keep the drop pipe in place. The mechanical advantage of this pump is incredible!

Windmills are also known for pulling up the entire pump system.

So far, we have pressurized the tank to 50 psi, not by an air compressor, but by pumping water into a conventional pressure tank. Each pound of pressure is equal to 2.3 feet of vertical lift (50 psi. x 2.3 feet = 115 feet). We are pumping from a static water level of 80′ with a 4″ cylinder and pressurizing a tank (80′ + 115′ = 195 feet of lift). Now that the wellhead is secured, we can continue testing.

So far, we have pressurized the tank to 50 psi, not by an air compressor, but by pumping water into a conventional pressure tank. Each pound of pressure is equal to 2.3 feet of vertical lift (50 psi. x 2.3 feet = 115 feet). We are pumping from a static water level of 80′ with a 4″ cylinder and pressurizing a tank (80′ + 115′ = 195 feet of lift). Now that the wellhead is secured, we can continue testing.

Do you know what size windmill is needed to pump water to an 195′ elevation operating a 4″ cylinder?

© 2013 Well WaterBoy Products LLC ♦ WaterBuck Pump™ ♦ Pedal Powered PTO™